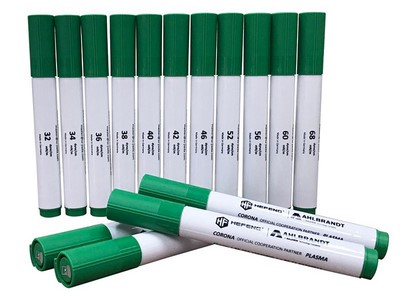

Dyne Pens

Quick Measurement of Surface Tension

Dyne pens, sometimes known as corona test pens, are a quick and easy means to verify if a substrate has sufficient surface tension for applications like printing, laminating or vacuum metallizing. These dyne pens allow you to effectively control the quality of the material after corona surface treatment, significantly reducing the loss caused by insufficiently treated materials.

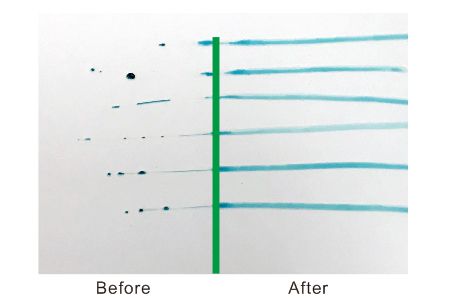

Usage of Dyne Pen

Using dyne pen to simply draw a line over the surface of the material to be tested, if the line is solid and does not shrink, that means you have achieved correct dyne level. If the line shrinks and breaks into droplets within 2 seconds then the dyne level is incorrect. The actual surface tension of material surface can be measured by applying dyne pens of different values.

Dyne Level Testing

- Before: the line breaks into droplets within 2 seconds.

- After: the line is solid and does not break into droplets.