HeFeng has provided innovative surface treatment solutions for a multitude of industry sectors with its plasma and corona treatment technologies. Our surface treatment solutions are flexible to meet the demands of materials like metal, plastic or glass, working environments and industries.

-

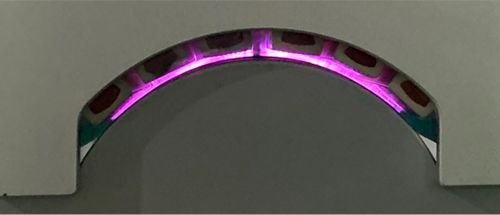

What is corona treatment

Corona treatment is a very effective way to increase the surface tension of various materials. By treating the material with high frequency and high voltage corona discharge, the surface of a substrate is given with adhesive properties so that it becomes more impressible to inks, coatings and adhesives.

-

Applications of corona treatment

Corona treatment, is known as dielectric barrier discharge (DBD), mainly used for surface treatment of plastic films and sheets. Before a substrate to be processed with ink printing, laminating, blown film / cast film extrusion, coating, gluing, modification and polymerization, corona treatment should be applied to increase the bonding characteristics of the substrate (increasing the dyne level).

-

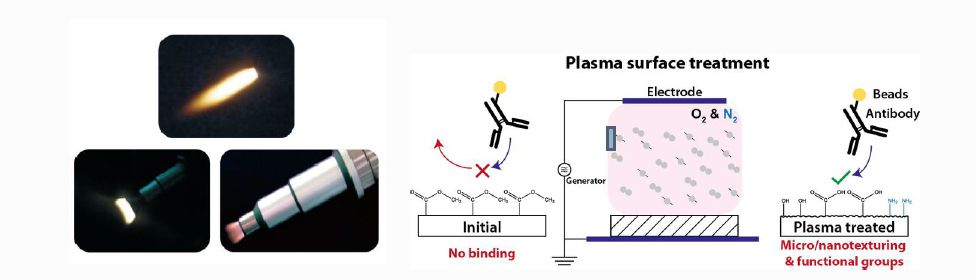

What is plasma treatment

Plasma is often referred to as the forth state of matter. It is based on the physical principle that by adding energy to matter so that solid becomes liquid, and the liquid becomes gaseous. If we continue to supply enough energy to the gas, the gas molecules will be ionized and generates the plasma. Atmospheric plasma and vacuum plasma are the two primary categories. The atmospheric air plasma treater utilizes blown ion or blown arc plasma technologies.

-

Functions of plasma surface treatment

- Surface cleaning: removal of dust or other contaminants, as well as elimination of static electricity;

- Surface activation: improving the wettability of surfaces;

- Surface coating: enabling the functionalization of the substrate surfaces;

- Increasing the penetration and improving bonding strength;

- Improving long-term durability and reliability of the bonding;

- Assuring the hydrophilicity;

-

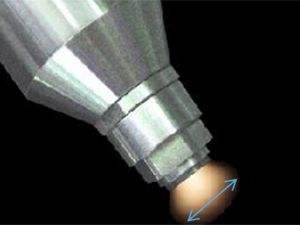

How to operate corona treater properly --- air gap adjustment

Optimal corona discharge air gap of 1-1.5 mm

-

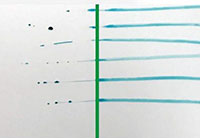

How to test surface tension --- dyne pen method

Before applying corona treatment or plasma treatment, the surface tension of the material has to be tested to determine whether the material being processed needs surface treatment or not. Dyne pen, or corona test pen, is a common test method.

Using dyne pen to simply draw a line over the surface of the material to be tested, if the line is solid and does not shrink, that means you have achieved correct dyne level. If the line shrinks and breaks into droplets within 2 seconds then the dyne level is incorrect. The actual surface tension of material surface can be measured by applying dyne pens of different values. -

Performance comparison before and after treatment

How to test surface tension --- sessile drop method

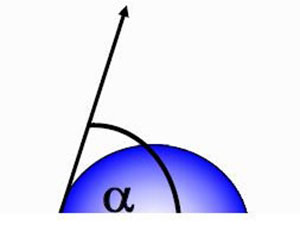

Before corona treatment

Before corona treatmentHigh contact angle

Poor adhesion

Low wettability

Poor printing effect

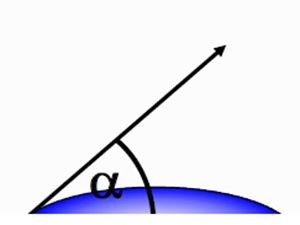

After corona treatment

After corona treatmentLow contact angle

Good adhesion

High wettability

Good printing effect

-

Selection of plasma treater

- Treatment width below 15mm, FR50B is recommended;

- Treatment width over 15mm, FR50BR is recommended (appropriate plasma nozzles should be selected according to the actual treatment area);

- In general, plasma nozzle diameter is same as the treatable area, e.g. if the treatment width is 25mm, plasma nozzle with diameter of 25mm should be selected (nozzle diameters are varied in a range of 20-55mm);

- FR50B nozzle height is 5-6mm from the material surface, and FR50BR nozzle height is 8-10mm from the material surface