Corona Treater Station (Non-conductive Webs)

Applications

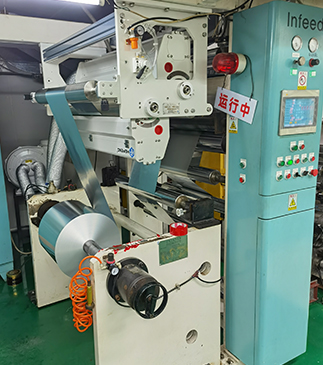

This corona treater station is typically designed for increasing surface tension of electrically non-conductive substrates such as PP, CPP, BOPP, PE, PET, HDPE, LDPE, PS, PI, PC, PA, PVC, ABS, non-woven, synthetic paper, thus improving the adhesion of inks, glues and coatings.

- FA-21

- FA-31R

- FA-31

- FC-32

- FC-52

- FC-52-2

- FR-72

- FR-31R

-

Technical Data

- Output power: 2-30 kW (configurable with CG2000/CD600 corona generators)

- Input voltage: 220VAC/380VAC

- Line speed: 1000 m/min (customizable)

- Web width: 300-11000 mm (customizable)

- Treatment: single-sided or double-sided treatment

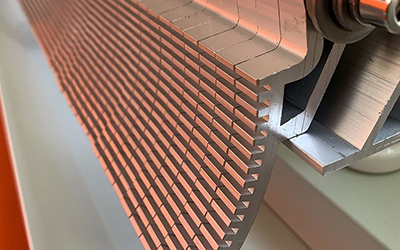

- Electrode: aluminum finned electrode

- Corona roller: rubber roller or silicone covered roller (optional)

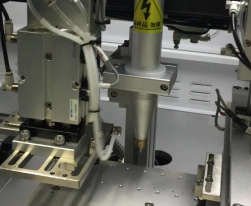

- Pneumatically actuated electrode assembly

- Motor/roller drive shaft

-

Technical Data

- Output power: 2-30 kW (configurable with CG2000/CD600 corona generators)

- Input voltage: 220VAC/380VAC

- Line speed: 5-400 m/min (customizable)

- Web width: 300-3000 mm (customizable)

- Treatment: single-sided treatment

- Electrode: metal electrode

- Applications: coating, slitting, lamination, extrusion, sheeting, etc.

-

Technical Data

- Output power: 2-30 kW (configurable with CG2000/CD600 corona generators)

- Input voltage: 220VAC/380VAC

- Line speed: 5-400 m/min (customizable)

- Web width: 300-3000 mm (customizable)

- Treatment: single-sided treatment

- Electrode: metal electrode

- Applications: coating, slitting, lamination, extrusion, sheeting, etc.

-

Technical Data

- Output power: 2-30 kW (configurable with CG2000/CD600 corona generators)

- Input voltage: 220VAC/380VAC

- Line speed: 5-400 m/min (customizable)

- Web width: 300-3000 mm (customizable)

- Treatment: double-sided treatment

- Electrode: metal electrode

- Applications: coating, slitting, lamination, extrusion, sheeting, etc.

-

Technical Data

- Output power: 2-30 kW (configurable with CG2000/CD600 corona generators)

- Input voltage: 220 VAC/380VAC

- Line speed: 150 m/min (customizable)

- Web width: 300-2500 mm (customizable)

- Treatment: single-sided or double-sided treatment

- Electrode: metal electrode or stainless steel electrode

- Pneumatic corona roller, spring electrode assembly

- Applications: blown film extrusion, slitting, lamination, extrusion, etc.

-

Technical Data

- Output power: 2-30 kW (configurable with CG2000/CD600 corona generators)

- Input voltage: 220VAC/380VAC

- Line speed: 5-400 m/min (customizable)

- Web width: 300-3000 mm (customizable)

- Treatment: double-sided treatment

- Electrode: metal electrode

- Applications: coating, slitting, lamination, extrusion, sheeting, etc.

-

Technical Data

- Output power: 2-30 kW (configurable with CG2000/CD600 corona generators)

- Input voltage: 220VAC/380VAC

- Line speed: 5-400 m/min (customizable)

- Web width: 300-3000 mm (customizable)

- Treatment: single-sided treatment (twice)

- Electrode: metal electrode

- Applications: coating, slitting, lamination, extrusion, sheeting, etc.

-

Technical Data

- Output power: 2-30 kW (configurable with CG2000/CD600 corona generators)

- Input voltage: 220VAC/380VAC

- Line speed: 5-400 m/min (customizable)

- Web width: 300-3000 mm (customizable)

- Treatment: single-sided or double-sided treatment

- Electrode: metal electrode

- Applications: coating, slitting, lamination, extrusion, sheeting, etc.

Related Products

- Corona Treatment Station (Conductive/Non-conductive Webs)

- Corona Treater Station (Non-conductive Webs)

- Sheet Corona Treater

- Corona Treatment Station (Corona Treatment on Aluminum Foil)

More than 20 years ago, HeFeng started its surface treatment development. Through years of experience, our range of surface treating equipment has been improved consistently and we have helped a number of manufacturers by delivering effective adhesion quality control. Backed by rich experience in corona and plasma treating, our team of surface treating experts can provide innovative surface treatment solutions to your adhesion problems relating to adhesive bonding, painting, printing, coating, cleaning, extrusion and lamination. Please explore our website to learn more about corona treatment and plasma treatment technologies for adhesion improvement and surface preparation.