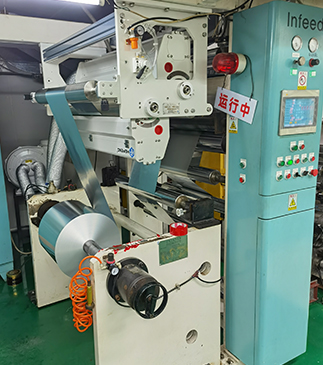

Corona Treatment Station (Corona Treatment on Aluminum Foil)

The corona treatment station is used for corona treatment on surface of aluminum foil. It utilizes high-frequency and high-voltage electricity generated by a corona treating machine. The electricity passes through a dielectric barrier to produce particles including low-temperature plasma. These high-energy particles bombard the surface of the aluminum foil, removing surface moisture, atmospheric gases, contaminants, and impurities. As a result, the surface becomes clean and activated, with an increased surface energy. The bombardment of high-energy particles also roughens the surface, increasing its effective surface area.

The discharge process produces ozone, which acts as a strong oxidizing agent. This polarization effect enhances the adhesive properties and bonding strength of the aluminum foil surface through multiple physical and chemical actions. Corona treatment stations are widely used in the aluminum foil slitting and coating industries.

Features

- The control cabinet circuit adopts international advanced technology to ensure continuous and fault-free operation of the corona treatment machine for 24/7.

- The control system uses PLC touch screen control, allowing convenient integration with the slitting machine and providing standard industrial Ethernet bus protocols for central control integration with other equipment.

- The control system has various alarm functions, including fan failure, air pressure failure, short circuit, main power failure, overheating protection, emergency stop, frame closure failure, rotation failure, underload and overload. It is equipped with a separate 3-color audio/visual alarm device.

- The discharge frame is aesthetically designed, with easy cleaning and maintenance of ceramic electrodes, and a well-sealed housing system to ensure ozone concentration around the equipment is no higher than 0.10 ppm.

- The opening and closing of the discharge frame are controlled by electromagnetic valves, which can be adjusted to specific winding speeds for operation.

- The corona treatment station is CE certified.

Technical Data

- Output power: 40-60 kW (configurable with CG2000/CD600 corona generators)

- Input voltage: 380VAC

- Line speed: 200-400 m/min (customizable)

- Web width: 1000-2000 mm (customizable)

- Treatment: double-sided treatments

- Electrode: ceramic electrode

- Applications: Primarily used for aluminum foil surface treatment, also suitable for copper foil, battery foil, and other materials

- Applicable machine types: slitting machines, coating machines, etc.

Related Products

- Corona Treatment Station (Conductive/Non-conductive Webs)

- Corona Treater Station (Non-conductive Webs)

- Sheet Corona Treater

- Corona Treatment Station (Corona Treatment on Aluminum Foil)